Article #26: Proper

Pump Piping Procedure – 10 steps

By

Dr. Lev Nelik, P.E., APICS

Pumping Machinery, LLC

It

should be realized that piping issues directly affect the pump’s life and its

performance. Bringing the pump to the

pipe in one operation and expecting a good pump flange or vessel fit is a very

difficult, if not impossible, task. When

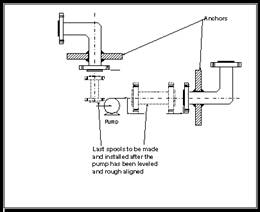

bringing the pipe to the pump the last spool (suction side and discharge side,

each) should always be left until the pump has been leveled in placed and rough

aligned. The final alignment will be a

“free bolt condition”, and, as may sound like a surprise to some, no “come-alongs”

would be needed. As an ultimate investement in common sense and proper

attention to details, - your pumps will last longer, with fewer failures of

seals, shafts, bearings and couplings. More equipment uptime, and less lost

production, will result in significant savings in dollars, and fewer headaches.

Step 1 (only for cases where there is

NO thermal growth – otherwise see Step 2 discussion)

At

this point the pipe should be securely anchored just before the last spool, to

prevent future growth towards the pumps flanges.

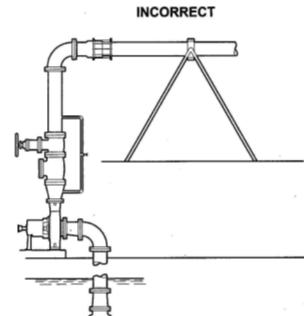

Figure 1 Occasional

usage of “anchors” (only if there is NO thermal growth (which is practice very

rare) for the pump piping – example would be a very short run of suction pipe

connecting it to a cold water tank, which keeps the pipe at essentially

constant (e.g. ambient) temperature, same as water in the tank. In most cases,

however, anchors should not be used (see Step 2 discussion)

The

final piping lay out should not be finalized until certified elevation drawings

are received from the engineering group or from the pump vendor. Once the final certified prints are received

the final isometrics can be completed and the piping takeoff can be done.

The

delivery of the equipment can either be early or it can be late in arriving at

the site. When the equipment is late it

is critical to have certified elevation prints of the equipment. The certified prints that the isometrics

required for the piping takeoffs can be made without impacting the construction

schedule. If the equipment is early, it

will arrive at the site prior to the construction team needing it for

installation. In such cases, early preparations must be made for long term

storage. It is customary to use oil mist

lubrication to keep the equipment in as-shipped conditions during the

storage. The pressurization of the

bearing housing and the casing with just 10 to 20 H2O pressure

prevents moisture and contaminants from entering the sealed areas and damaging

the components. The early delivery of

equipment to the site has the advantage of allowing for verification of the

actual measurements.

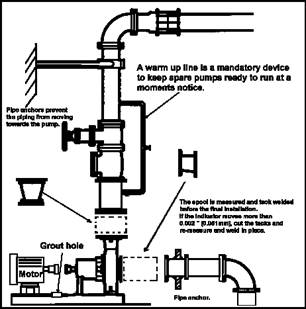

Step 2

Once

the location of the equipment is set, the baseplate can be put in place,

leveled and rough-aligned, with the equipment mounted. Rough alignment of the equipment should be

done prior to building the grout forms. To avoid stresses caused by thermal

expansion of pipes, expansion loops should be installed in suction and

discharge lines. The “sliding” pipe supports near pump suction and discharge

are required to eliminate weight loads of piping on them pipe, which can cause

excessive loads and misalignment, leading to seal failures, bearings,

couplings, etc. However, “anchors” (three dimensional restraints) should not be

used, as these could cause significant stresses and casing distortions due to

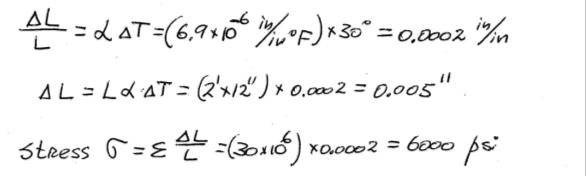

thermal expansion. Consider, an example (Fig. 2C) of incorrectly placed

“anchor” (restraining growth in ALL directions, i.e. not simply a vertical

“sliding” support), even 2 feet away from the pump suction, and the case where

the pipe expands by only 30 degrees F (morning to afternoon):

For

the pipe you use, the area of contact between the pump and pipe flanges depends

on the size of the pipe. Assume, for example, a 20 in2 contact area

(or use your pipe/flange number). The resultant force on the pump will be:

F =

6000 x 20 = 120,000 lbs – very high. It will distort the pump casing, feet,

shafts, etc., causing problems. If, in addition to that, you are pumping hot

product, the piping expansion problem could be so much worse. But even the

daily fluctuations of ambient temperature alone could cause problems, as shown

in a sample calculation above.

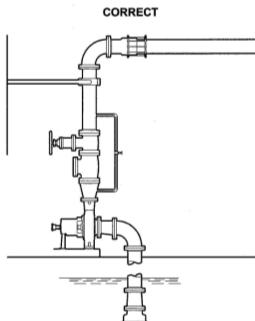

A.

Correct: sliding support does not retrain the piping to slide up/away B. Piping restrained (can

not slide up/away), high thermal expansion loads C. “Anchor”

will (problem!) allow pipe to expand towards/into the pump,

causing high axial loading

Figure 2 Rough alignment

phase (note that the motor and the pump are not coupled yet and the baseplate

is still sitting free, not grouted

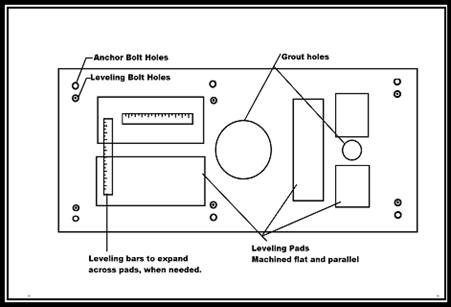

Step 3

Once

you are satisfied with the rough alignment, remove all the equipment (pump, motor gearbox, etc) from the

baseplate. Level the baseplate to

maximum out of level of 0.025" (0.06 mm) from end to end in two

planes. Use machined pads as the base

for the leveling instruments. Inspect the foundation for cleanliness, and if

not clean, use solvent to remove grease and oil.

Figure 3 Baseplate

leveling pads and grout location

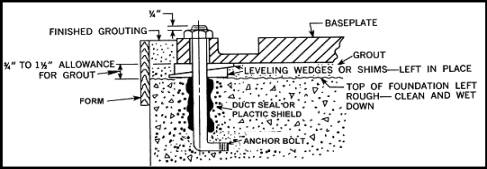

Step 4

Allow

time for the cleaning substances to evaporate.

Form the base using the appropriate techniques to allow for the weight,

temperature rise and fluidity of the grout material. Grout the base using epoxy grout. Allow the grout to cure, following the grout

manufacturer’s recommendations. This

normally requires 24 hrs at 80° F (27°C). Remove the forms and clean all sharp

residue and edges from the foundation.

Figure 4 Typical

anchor bolt and leveling wedges

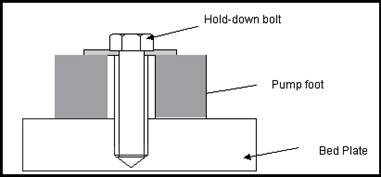

Step 5

The

rough alignment step, which we mentioned above, is critical to minimize the

changes that will be required to appropriately fit the piping to the pump. At the last stage, when the final spools are

installed, the final alignment will be achieved with small adjustments. This will minimize the adjustments required

on the motor feet/bolts. Unfortunately

(motor manufacturer’s take heed!), motor hold-down bolts are often too tight

and allow only for small adjustments to the motor before becoming bolt

bound. Motor manufacturers could improve

this situation significantly if motor feet were slotted, by design, rather than

drilled for bolts. Figure 5 shows

the tightness of space available to insert the foot hold-down bolt.

Figure 5 Potential

bolt-bound situation due to tight clearances between bolt, feet and base

This

illustrates once again why good alignment at step 3 can save time and the cost

of having to alter motor feet (a nightmare) by slotting or reaming.

Step 6

Reinstall

the pump and the motor on the baseplate.

Rough align the equipment again, using reverse indicator or laser

alignment or similar accurate techniques.

Figure 6 Rough alignment after grouting

It

should be now easy to fine-tune the motor movement within the allowable

alignment target without becoming bolt bound.

This is possible because of the rough alignment during the prior step (Step 4) was

completed. Note: Never install

shims under the pump feet. If the shims

are lost or misplaced then alteration to the piping may be required to get the

pump within the required alignment specification. The normal procedure is to place 0.125"

(3.2 mm) thick shims under the motor feet.

This allows for adjustments that will be required during final

alignment.

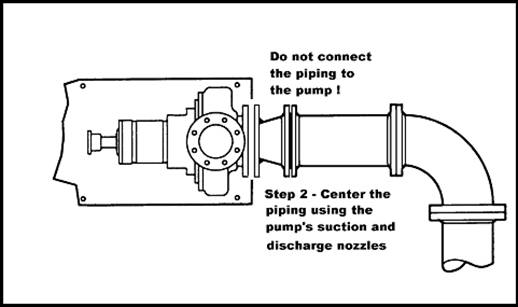

Step 7

Make

up the final spool pieces for the suction and discharge spaces. Bring the piping to the pump now.

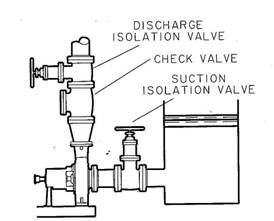

Figure 7 Illustration

of the final connection of the suction piping.

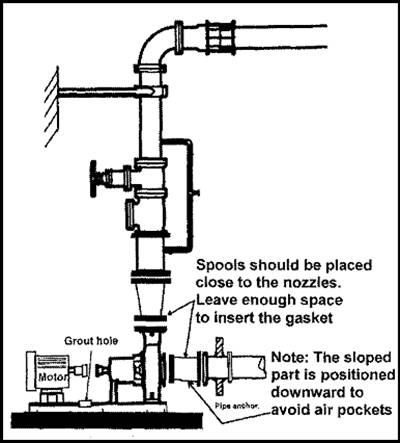

Step 8

Warning! – “anchor” is placed erroneously - it will

restrain the pipe thermally moving away from the pump free: the pipe will

expand from the anchor into the pump! (see discussion

in Step 2)

Figure 8 Final piping

As

a final alignment step, bring the piping to the equipment; take final

measurements, tack weld the spools in place.

At this time the spools can be removed and taken back to the hot work

permit area to finalize the weld. Leave

a square and parallel gap between the flange faces. The gap should be wide enough to accommodate

the size of the gasket required, plus 1/16 - 1/8”, depending on piping sizing.

(This is the only distance over which the piping will be pulled. However,

because it is properly anchored before the spool pieces, this length is

short, and stresses are minimized).

Final align the equipment, taking into account hot and cold operating

conditions, using two indicators on the pump shaft coupling area.

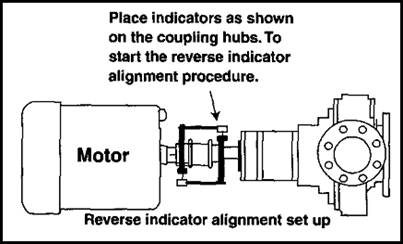

Step 9

Figure 9 Overhead

view of the motor and pump

As

the piping is tightened into place, the shaft shall not be moved more than

0.002" (0.005 mm), otherwise modify the spool pieces until the piping

misalignment is fixed.

Several

clues are common to piping misalignment.

These clues come via the way of mechanical seal and or bearings running

hot, and failures. A quick analysis of

the failed parts can clearly show the evidence of piping misalignment. To make a final confirmation of the symptoms,

unbolt the piping while measuring the movement in the vertical and horizontal

plan. Again, the piping that moves more than

0.002" (0.005 mm) must be modified to correct the situation.

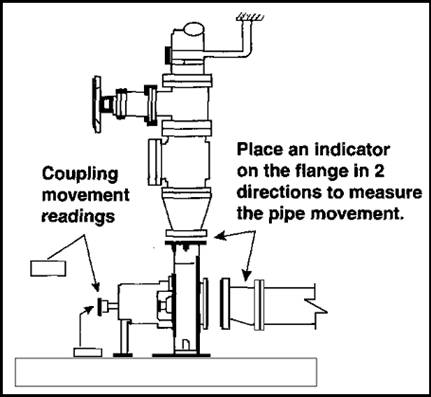

Step 10

Place

and indicator in horizontal and vertical planes, using the motor and pump

coupling.

Uncouple

the pump and motor, while watching the indicator movement. Start unbolting the flanges, and continue

watching for movement in the indicators.

If the needle jumps over 0.002" (0.005 mm) the piping has to be

modified to improve the pump’s performance.

Figure 10 Piping

alignment verification

References

1.

1) Pump Standards, Hydraulic Institute publication, ANSI/HI 1.1‑1.5‑1994,

2.

2) API 610 Standard for centrifugal pumps, 8th Edition, American Petroleum

Institute, Washington, DC, August, 1995

3.

3) API 676 Standard for rotary pumps, 2nd Edition, American Petroleum

Institute,

4.

4) Equipment Testing Procedure for Centrifugal Pumps (Newtonian

liquids), 2nd Edition,

5.

5) AlChE Equipment Testing Procedure for Rotary positive displacement

pumps (Newtonian liquids), Second printing,

6.

6) Nelik L., "Centrifugal and Rotary Pumps: Fundamentals with

Applications", CRC Press,

7.

7) AlChE Equipment Testing Procedure, 1999,

8.

8) L. Rizo, L. Nelik,

“Piping-to-Pump Alignment”, Pumps & Systems, April 1999

E-Mail your questions and

suggestions to: