By

President

Pumping Solutions, Inc.

Progressive cavity (PC) pumps are self-priming rotary positive displacement pumps with smooth output flow.† They are capable of pumping both thick and thin fluids, and do very well at pumping liquids with high solids and abrasive content.† These capabilities have made the progressive cavity pump THE pump of choice for many applications in the wastewater treatment industry.†††

In recent years, advances in pump design, electronic monitoring, and materials of construction have allowed the PC pump to handle more severe application conditions, while at the same time improving the pumpís energy efficiency and decreasing maintenance requirements.†

The purpose of this article is to give a basic overview of the pumps operating principle and review some of the new technical innovations that end users might be able to benefit from.

Rene Moineau invented the progressive cavity pump in

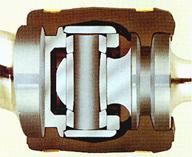

The PC pump is made of three major sections:

(Courtesy

In recent years many improvements have been made in these three areas to improve the pumps overall performance.

Improvements

in drive train design:

|

Features |

Benefits |

|

Close

coupled or Block Design†††††††† |

Smaller

pump package Less

Upfront Cost No

drive alignment issues† Eliminates

the need for safety guards |

|

Easy

|

Simplifies

seal service, reduces down time |

|

Sealed

Pivot Style Universal Joints |

Fewer

parts Long

lasting and easy to work on Protects

Drive-shaft, Coupling Rod and Rotor from damage. |

|

|

Better

NPSHR values Higher

Volumetric efficiencies Higher

% Solids capabilities |

Improvements

in Suction Housings:

|

Features |

Benefits |

|

Oversized

Open Hopper Inlets |

Handle

thicker liquids |

|

Special

Compression Zones |

Increased

volumetric efficiency |

|

Oversized

Hopper With Double |

Eliminates

bridging Handles

filter cake up to 55% solids |

Improvements

in Pumping Element:

|

Features |

Benefits |

|

New

2 x 3 rotor/stator geometry |

Increased

flow per revolution and reduces initial pump cost. |

|

Equal

Wall Stators |

Doubles

pressure capability per stage |

|

Tie

Rod Construction |

Easy

stator change out with standard socket set |

|

Hollow

Cast Rotors |

Increase

rotor and stator service life |

|

Temperature

Probe |

Protects

against dry run |

|

Ductile

Coated Chrome Rotors |

Extend

wear life of rotor Does

not flake off like standard chrome coatings |

Let us know if you may have any questions. We would be glad to help. E-Mail your questions to: