Article 20:

WHAT HAPPENS WHEN A PUMP NO LONGER

OPERATES AT OPTIMUM CONDITIONS (Part 2)

In June of 2003, we started to discuss hydraulic implications of

pumps operating to the left of the best efficiency point (BEP). Low efficiency,

high radial loads, noise, vibration - become a real problem when that happens.

Damage to the seal, shaft, couplings and poor reliability are a real and direct

result of such operation. However, is it possible to quantify “Reliability”? What is

the impact on the equipment Life Cycle Cost, when a pump operates, say, 40%

off-peak? How much does this cost the plant? – not just in energy alone (that

aspect we covered in June), but – in terms of … seal replacement … bearing life

… coupling repairs … cavitation and recirculation damage cost … and so on. Is

it possible to derive at some factors which would relate the maintenance

dollars spent – to the inefficiency of the pump operation?!

In Part 1 (Article 19), we talked about the

effects of pumps operating at off-peak flow on efficiency and did an estimate of the wasted energy. That

discussion now has been published as so please feel free to examine it there.

This month, we are now examining the effect of such off-peak operation on

radial load, cavitation damage, and other aspects – and linking these to the

estimate of the actual plant costs. To do that, some assumptions had to me

made, and we would like to hear from you if you agree, or disagree, with these

assumption. As times goes on, this fledgling theory of operation-to-reliability

costing method may develop into a more comprehensive method, and the input from

the users will help make the next step.

In the recent years, the importance

of improving the overall reliability and plants uptime resulted in renewed

attention to the reliability assessment of the individual system components.

Pumps constitute one of the major classes of the plant components, and directly

contribute to the overall economics of the life cycle evaluation.

Let’s take a look, for example, at the advantages of the use new materials,

such as structural composites, with regard to parts upgrade program (pump

impellers, wear rings and bushings), as well as complete pumps. The reliability

and savings can be achieved with focus on the following:

Significantly reduced weight (80% lighter then metal) with

excellent tensile strength, approaching metals

Superior chemical resistance for most demanding tough chemicals

Abrasion resistance – up to 15% solids

Dry-running – continuous 3-D interwoven woven graphite fibers

providing good self-lubricating properties

Cavitation resistance exceeding bronze and stainless steel

Improved rotordynamics, longer seal life and bearing life

extension

Quality: these thermoset parts 5-axis machined from solid block

(no unbalance), as compared to injection-molded or cast thermoplastics (voids

and crevices result in unbalance)

Higher efficiencies due to tighter clearances allowed and superior

finish

Let’s also compare open versus

closed impellers. Open impellers have traditionally been accepted as a standard

design configuration of the ANSI pumps for chemicals. Initiated as far back as

1961 (originally called an AVS Standard), ANSI pumps have been installed in

numerous plants, and established a convenient and accepted standard to which

both manufacturers, and the end users, could readily comply. ANSI pumps, made

by different pump manufacturers would adapt to the same piping and baseplate

dimensions, thus making them dimensionally interchangeable, although the

internal parts geometry differs from one manufacturer to another.

The main advantage of the open

impeller design is cost. They are easier to cast and clean up at the foundry,

especially in case of sand casting process, which is often applied to iron

construction. Stainless steel designs are typically made using precision

patterns, and cleanup of passages from the mold residue is less of an issue,

but still a less expensive operation.

With the advent of the mag-drive

designs, however, closed impellers became a necessity, mainly due to a need to

reduce the axial thrust. Carbon or silicon carbide thrust washers, lubricated

by the products, do not have the same load capability as antifriction ball

bearings. Thus, a need to reduce the loads necessitated the change toward the

closed impeller designs.

However, substantial reliability

benefits can be achieved by replacing open impellers by closed impellers, -

even for the standard designs that utilize single or double seals, or packings.

Although the benefits of this approach have always been understood, the

quantifiable justification has become possible only recently, as new

reliability methods and approaches became available, using a Life Cycle Cost

Method (LCM).

Benefits

The benefits of the closed impellers

are materialized in (4) following areas:

Bearings Life

Seals Life

Efficiency improvement

NPSH

1) Bearings

As a typical example, consider a typical

MTX frame ANSI end suction overhung open impeller pump. Typical radial load FR

= 400 lbs and axial load is FA = 900 lbs. The equivalent dynamic

load is calculated as:

P = XFR + YFA

= 0.63 x 400 + 1.24 x 900 = 1368 lbs

This load is carried by the 5306A

double row ball bearing, which has a dynamic load coefficient C = 16,400 lbs,

which results in L10 life calculation as:

L10 = (C/P)3 x

106/(60xRPM), and adjusted by the a23 coefficient,

reflecting oil optimization (typically a23 = 2.5)

Thus, Lna = 2.5 x

(16,400/1368)3 x 106/(60x3600) = 20,052 hrs, i.e. 2.3

years.

ANSI spec requires 17,500 hrs

bearings life, which is approximately in agreement with calculations.

However, the axial load (FA)

used in these calculations, can change dramatically, depending on the position

of the impeller within the volute, the height of the pump-out vanes (POV), and

the gap between the pump-out vanes and the casing wall. The design value, used

at above calculations, is at the assumed design value of 0.060” gap between the

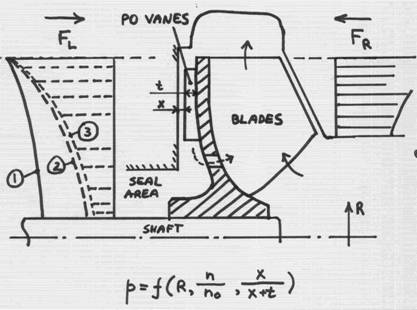

POV and the wall. The main reason

to use pump-out vanes (POV) is to change the pump axial hydraulic thrust:

The

rotation of the impeller results in “dragging into rotation” of the fluid in the

gap between the impeller and casing walls. This is similar to a motion of a

teaspoon in a cup, or a disk spinning inside containment. The resulting motion

is referred to as “forced vortex”. Such vortex sets-in in the front and back

gaps – between the casing walls and the impeller front (shown on the right) and

a back hub (shown on the left). The pressure distribution in the gap is

parabolic – higher at the impeller OD, and gradually reducing towards the shaft

centerline.

Pressure

time area is force – which is exerted on the impeller from both sides (FR

and FL). The difference between these forces is hydraulic axial

thrust, which is ultimately transmitted to the bearings, and thus is desirable

to be small. This pressure at a given position in a gap depends on the radius,

rotational speed of the fluid (divided by the impeller rotational speed), and

the gap.

Curve

(1) shows the static pressure distribution behind the impeller hub without the

pump-out vanes. As we know from basic hydraulics, - the faster the fluid moves,

the lower the static pressure is. So, if we could make the fluid in the gap to

rotate faster, the static pressure would be reduced, and the force FL

to become smaller – closer, and hopeful equal to the FR – to reduce,

or eliminate the net thrust.

Without

the POV, the fluid in the gap is rotated only by the friction (drag) of the

impeller hub wall. It rotates with the same speed as the impeller right at the

impeller wall surface, but (so called “no-slip-condition”) is not rotating at

the casing wall, since that wall is stationary. Thus, on the average, the bulk

of the fluid in the gap is spinning at the angular velocity equal to half

of the angular velocity of the impeller.

But,

if we add the POV, the fluid becomes “trapped” within the POV space, and thus

rotates with the same speed as the impeller – i.e. double of what the fluid

does in the absence of the POV. This, of course, assuming the gap between the

POV and the casing wall is (theoretically) zero (x=0). The number of the POVs

actually does not have to be equal to the number of the impeller main blades,

but often is, due to casting production process, for simplicity.

Obviously,

the gap “x” can not be zero, so the actual reduction of the pressure profile

(curve marked as “2”, is less, depending on the gap “x”. And, if this gap

becomes too large, the effect of the POV diminishes, and eventually disappears.

It turns out that, the POV are most effective at x=0, and become completely

non-effective when x=t, i.e. when the liquid gap (x) becomes

equal to the height of the pump-out vanes (t). (Papers are

written on this subject, such as a well known Zanker’s paper), explaining whys

and whats, and those of you who have a couple of sleepless nights to study them

– let us know, and we will get you the material).

The

balancing holes are also used to reduce pressure distribution, i.e. a similar

idea as the pump-out vanes. In fact, this is why they are called “balancing”.

To be effective, the impeller must have a tight clearance between it and a

casing (not shown on a picture above), to separate the higher pressure zone,

from a lower pressure zone. The balancing holes thus connect the back of the

impeller with the inlet area, where pressure is low (close to suction). Some

leakage will occur, reducing the efficiency. If there is no clearance, such as

shown above, the leakage will be greater, reducing the efficiency even more.

Another

reason for the POV is to reduce the pressure at the mechanical seal area. The

effect of these vanes can be very strong, and, sometimes even result in

creating vacuum, and boiling out of the liquid. This could be trouble, as

mechanical seals do not like to operate in a vapor environment.

Regarding

the performance – there is price to pay for the thrust balance, as the

additional power required to spin the liquid faster takes away the efficiency.

This is why, the higher energy pumps, such as API, or boiler feed, rarely have

the pump-out vanes, while the ANSI pumps, which are relatively lower horsepower

units, have these.

Note

the picture above shows an open impeller. The front gap, between

the impeller and the casing, must be tight (typically 0.005 – 0.015”, depending

on a pump size). The challenge is thus to maintain both front and back gaps

small – from the efficiency and thrust standpoint. Closed

impellers solve this problem, but at the expense of reduced ability to handle

stringy, such as fibrous, solids.

Regarding

the “reverse vane” impeller. The impeller shown above is a standard design, such

as, for example, manufactured by Goulds, model 3196. To adjust the front

clearance, the rotor must be pushed against the casing, and then backed-off by

the amount of design clearance. It is sometimes desirable to keep the casing

piped-up, as it is somewhat a chore to re-pipe it. This requires re-setting of

the front gap, during maintenance, on site – and, if it rains or snows – you

freeze and catch a cold!

If

the impeller is “turned around”, such that the clearance gap is between the

impeller and the stuffing box (or a sealing chamber), then this clearance can

be set at the shop, and the rotor can then be simply brought to a casing and

bolted on quickly. Example of such design is former Durco

Clearly,

the perceived advantage, widely publicized in the past by the manufacturers, of

the ability to adjust the impeller front clearance to compensate for wear is

quickly, can do more harm then good: as impeller is adjusted forward to close

the worn out gap, the back clearance increases – by the same amount. The

increased gap between the POV and the casing wall can effect pressure

distribution dramatically. The resultant axial thrust can actually triple, i.e.

FA = 3 x 900 = 2700 lbs

Additionally,

as impeller wears out, the removed metal causes radial unbalance, which adds to

a hydraulic thrust. Estimates vary, but 50% increase in radial load is quite

possible, so that FR = 1.5 x 400 = 600 lbs

The

equivalent dynamic load then becomes: P = 0.63 x 600 + 1.24 x 2700 = 3736 lbs, which

impacts bearings life dramatically:

Lna = 2.5 x (16,400 / 3736)3 x 106/(60x3600)

= 979 hrs = 1.3 months !

2)

Seals

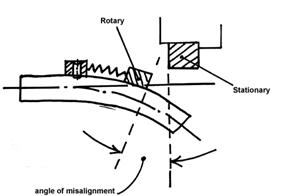

The

impeller wear, and the resulted unbalance, results in increased radial load and

shaft deflection:

Seal

manufacturers have done research which shows exponential deterioration of seal

life, including leakage and failures, when the angular misalignment exceeds

0.002”. At 50% increased radial load, a normal projected seal life of 2 years

can be reduced to less then 6 months.

The

problem can in fact become worse if the impeller is adjusted (as was discussed

above) axially due to wear, because this results in reduced seal spring

tension, lowering closing force and initiating premature leak.

3)

Efficiency

Theoretically,

an open impeller with negligible front clearance is somewhat more efficient

then a closed impeller. However, efficiency drops very quickly as actual front

clearance is increased due to wear. When initial 0.005” front clearance is

opened up to 0.010”, a pump can loose 10% efficiency due to increased leakage,

and at 0.015” there would be approximately another 10% efficiency reduction.

Obviously, none of this is an issue for closed impellers.

4)

NPSH

The

impact on NPSHR is similar to the efficiency. The increased front leakage

effects the NPSHR and could add another 2-4 feet when clearance doubles. The

R-ratio (NPSHA/NPSHR) varies form one installation to another, but a typical

rule is to have at least 5 feet NPSHA above the NPSHA required. When almost

half of this margin is taken away to front leakage, the R-ratio can become too

close to the NPSHR and the cavitation bubbles that begin to form even before

the NPSHA reaches the value of performance loss, become active enough to cause

caviation damage:

It

is difficult to quantify the decrease in impeller useful life due to worsen

cavitation condition, since there is no known statistics published on the

average life of the impeller as function of NPSHA, and some reasonable

assumptions may be required. If we assume that a non-cavitation impeller could

last 10 years until replacement, the reduction of the NPSHA margin from 5 feet

to 2.5 feet would affect the life in direct proportion, i.e. reducing it to 5

years. More studies, however, would be required to quantify this particular

effect on reliability.

LIFE

CYCLE APPROACH

In

order to compare different designs using Reliability methods, a Cycle Basis

needs to be established, which is also applied to other types of components. A reasonable

basis for comparison is a 5 year interval. Another assumption is made that,

during this time cycle, a pump operates in several descretised steps of

operation, for example 20% in regime 1, another 20% in regime 2, and so on.

This allows a more uniform distribution of various regimes of operation

throughout the cycle and a better averaged comparison. We will apply this

method to each of the selected elements that are affected by the forcing

function, such as:

a)

Bearings – life decreasing from 2.3 years to 1.3 (0.21 years) months within

five zones for the purpose of averaging:

The

above distribution can be a safe assumption when a continuous statistical data

is limited. Otherwise, if the load is known at each interval, and the bearing

life can be calculated at each of the intervals, the averaging can be done by

summing the life at the intervals and dividing by the total time span (5 years

in case if Cycle Basis is selected as 5 years).

For

linear distribution, the averaged weighted life would be:

(2.3

+ 1.75 + 1.2 + 0.65 + 0.1) / 5 = 1.2 years

b)

Seals – using similar linear function (2 years life at interval 1, reducing

linearly to a calculated 0.6 years life at interval 5), we get:

(2

+ 1.62 + 1.25 + 0.88 + 0.5) / 5 = 1.1 years

c)

Efficiency - assuming pump efficiency

drops from 70% to 58% (70, 65, 60, 55, 50), we get the weighted average:

(70+65+60+55+50)

/ 5 = 60%

To

relate this to the life cycle factor, we need to evaluate the energy savings

due to efficiency difference. Assuming a pump with a 10 hp motor, running 100%,

at $0.06 per kWxhr, this results in:

10

x 0.746 x 24 x 365 x 0.06 x 0.70 = $2755

10

x 0.746 x 24 x 365 x 0.06 x 0.60 = $2352

Annual

energy savings $402 per pump, which is roughly a 1 year payback period basis a typical

cost of a replacement impeller.

d)

NPSH margin – assume reducing from 5 feet margin to 2.5 feet (5, 4.4, 3.8, 3.1,

2.5), we get the averaged cycle value of:

(5+4.4+3.8+3.1+2.5)/5

= 3.8 feet

If a

10 year life is assumed with a full specified margin (5 feet), then the reduced

life is 3.8/5 x 10 = 7.6 years

Note:

the actual life of impellers also varies depending on applications and pump

types. Double suction cooling water pumps, for example, are notorious for

NPSH-related problems (Ref. [10]).

COMPARISION

Open Closed

Bearings

life factor 1.2 yr 2.3 yr

Seals

life factor 1.1

yr 2 yr

Efficiency

factor 0 yr 1 yr

NPSH life factor 7.6

yr 10 yr

Total: 9.9

yr 15.3 yr (54% improvement)

MTBF

Having

established life factor comparison, the next step is relate these to the Mean

Time between Failures (MTBF), which is typically known relatively accurately

for a given plant. Assume for example, a plant averages 3 years MTBF. The 54%

improvement, calculated above, would increase the MTBF to 3 x 1.54 = 4.6 years.

What

does an improvement in 1.6 years, per pump, in MTBF mean to a typical plant?

1.6

added years is equivalent to an improvement of 1/1.6 = 0.62 failures pre year.

The cost of equipment failures is a total of individual components: parts,

labor and lost production. While replacing of impellers, seals, bearings, and

other parts is costly, a cost of lost production can even more significant. For

a typical chemical plant with thousands of pumps, this could be a very

significant number. The cost of a lost production also varies from one plant to

another, and literature has values anywhere from $5,000 per hour to $200,000

per hour. At a $10,000 per hour value of lost production, each pump would

result in 10,000 x 0.62 = $6,200 difference, and, with a population of 1000

pumps at a plant, this amounts to 1000x6200 = $6.2M for a plant!

Clearly,

these vary from one plant to another, but the importance of the issue is

clearly there, and it can not be ignored.

Example

above: metal impeller, reduced life due to corrosion attack. Composite

(continuous graphite fibers in epoxy matrix), not affected by chemical attack.

Also,

an ANSI pump, installed at the chemical plant, resulted in extended life due to

lowered weight, as well as improved chemical resistance. These cases are

currently being prepared, and will be included with the final manuscript.

A

retrofit program of converting open impellers to closed impeller design present

substantial, real and immediate benefits to the end user. For a typical

chemical plant, or similar operating facility, this could be thousands, or even

millions of dollars, saved in maintenance, repair and production budgets. The

conversion process is straightforward and technically sound. The best approach

is to establish a planned program of replacing, starting from the worst

operating units and continuing to the next level, driving the plant reliability

record continuously upward.

New

technologies, such as engineered structural composites, present a timely and

effective opportunity to achieve maximum benefits and quickly. The combined

benefits of significantly reduced weight, substantial improvements in chemical

resistance, excellent abrasion characteristics, and superior cavitation

resistance, makes Simsite a material of choice for such program.

We

welcome your input on this topic, and will be glad to post your comments and

opinions at the Pump Magazine On-Line commentary board.

Dr. Lev Nelik, P.E., Apics

Pumping Machinery, LLC

August, 2003