Article #10: PUMP-OUT VANES

This article came out

in response to a question from our reader:

Could you explain how an ANSI pump impeller clearance (both open

vane impeller with back pump out vane and reverse vane impeller with balancing holes)

setting affect pump performance? What are the advantages and disadvantages of

these impellers?

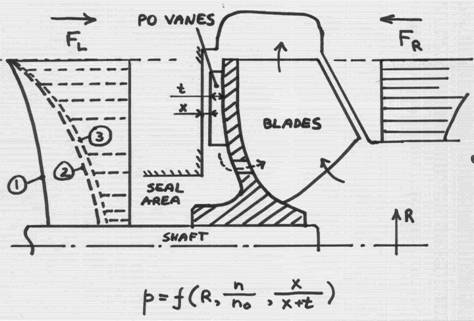

The main reason to

use pump-out vanes (POV) is to change the pump axial hydraulic thrust. Take a

look at the picture:

The rotation of the

impeller results in “dragging into rotation” of the fluid in the gap between

the impeller and casing walls. This is similar to a motion of a teaspoon in a

cup, or a disk spinning inside containment. The resulting motion is referred to

as “forced vortex”. Such vortex sets-in in the front and back gaps – between

the casing walls and the impeller front (shown on the right) and a back hub

(shown on the left). The pressure distribution in the gap is parabolic – higher

at the impeller OD, and gradually reducing towards the shaft centerline.

Pressure time area is

force – which is exerted on the impeller from both sides (FR and FL).

The difference between these forces is hydraulic axial thrust, which is

ultimately transmitted to the bearings, and thus is desirable to be small. This

pressure at a given position in a gap depends on the radius, rotational speed

of the fluid (divided by the impeller rotational speed), and the gap.

Curve (1) shows the

static pressure distribution behind the impeller hub without the pump-out vanes.

As we know from basic hydraulics, - the faster the fluid moves, the lower the

static pressure is. So, if we could make the fluid in the gap to rotate faster,

the static pressure would be reduced, and the force FL to become

smaller – closer, and hopeful equal to the FR – to reduce, or

eliminate the net thrust.

Without the POV, the

fluid in the gap is rotated only by the friction (drag) of the impeller hub

wall. It rotates with the same speed as the impeller right at the impeller wall

surface, but (so called “no-slip-condition”) is not rotating at the casing

wall, since that wall is stationary. Thus, on the average, the bulk of the

fluid in the gap is spinning at the angular velocity equal to half

of the angular velocity of the impeller.

But, if we add the

POV, the fluid becomes “trapped” within the POV space, and thus rotates with

the same speed as the impeller – i.e. double of what the fluid does in the

absence of the POV. This, of course, assuming the gap between the POV and the

casing wall is (theoretically) zero (x=0). The number of the POVs actually does

not have to be equal to the number of the impeller main blades, but often is,

due to casting production process, for simplicity.

Obviously, the gap

“x” can not be zero, so the actual reduction of the pressure profile (curve

marked as “2”, is less, depending on the gap “x”. And, if this gap becomes too

large, the effect of the POV diminishes, and eventually disappears. It turns

out that, the POV are most effective at x=0, and become completely non-effective

when x=t, i.e. when the liquid gap (x) becomes equal to the height

of the pump-out vanes (t). (Papers are written on this subject, such as

Zanker’s, explaining whys and whats, and those of you who have a couple of

sleepless nights to study them – let us know, and we will get you the

material).

The balancing holes

are also used to reduce pressure distribution, i.e. a similar idea as the

pump-out vanes. In fact, this is why they are called “balancing”. To be

effective, the impeller must have a tight clearance between it and a casing

(not shown on a picture above), to separate the higher pressure zone, from a

lower pressure zone. The balancing holes thus connect the back of the impeller

with the inlet area, where pressure is low (close to suction). Some leakage

will occur, reducing the efficiency. If there is no clearance, such as shown

above, the leakage will be greater, reducing the efficiency even more.

Another reason for

the POV is to reduce the pressure at the mechanical seal area. The effect of

these vanes can be very strong, and, sometimes even result in creating vacuum,

and boiling out of the liquid. This could be trouble, as mechanical seals do

not like to operate in a vapor environment.

Regarding the

performance – there is price to pay for the thrust balance, as the additional

power required to spin the liquid faster takes away the efficiency. This is

why, the higher energy pumps, such as API, or boiler feed, rarely have the

pump-out vanes, while the ANSI pumps, which are relatively lower horsepower

units, have these.

Note the picture

above shows an open impeller. The front gap, between the

impeller and the casing, must be tight (typically 0.015 – 0.030”, depending on a

pump size). The challenge is thus to maintain both front and back gaps small –

from the efficiency and thrust standpoint. Close impellers solve

this problem, but at the expense of reduced ability to handle stringy, such as

fibrous, solids.

And finally, regarding

the “reverse vane impeller”. The impeller shown above is a standard design,

such as, for example, manufactured by Goulds, model 3196. To adjust the front

clearance, the rotor must be pushed against the casing, and then backed-off by

the amount of design clearance. It is sometimes desirable to keep the casing

piped-up, as it is somewhat a chore to re-pipe it. This requires re-setting of

the front gap, during maintenance, on site – and, if it rains or snows – you

freeze and catch a cold!

If the impeller is

“turned around”, such that the clearance gap is between the impeller and the

stuffing box (or a sealing chamber), then this clearance can be set at the

shop, and the rotor can then be simply brought to a casing and bolted on

quickly. Example of such design is former Durco Mark III design.

As you can see, each

design option has advantages, and disadvantages, and the ultimate decision

remains with a specific application requirements.

We welcome your comments to: